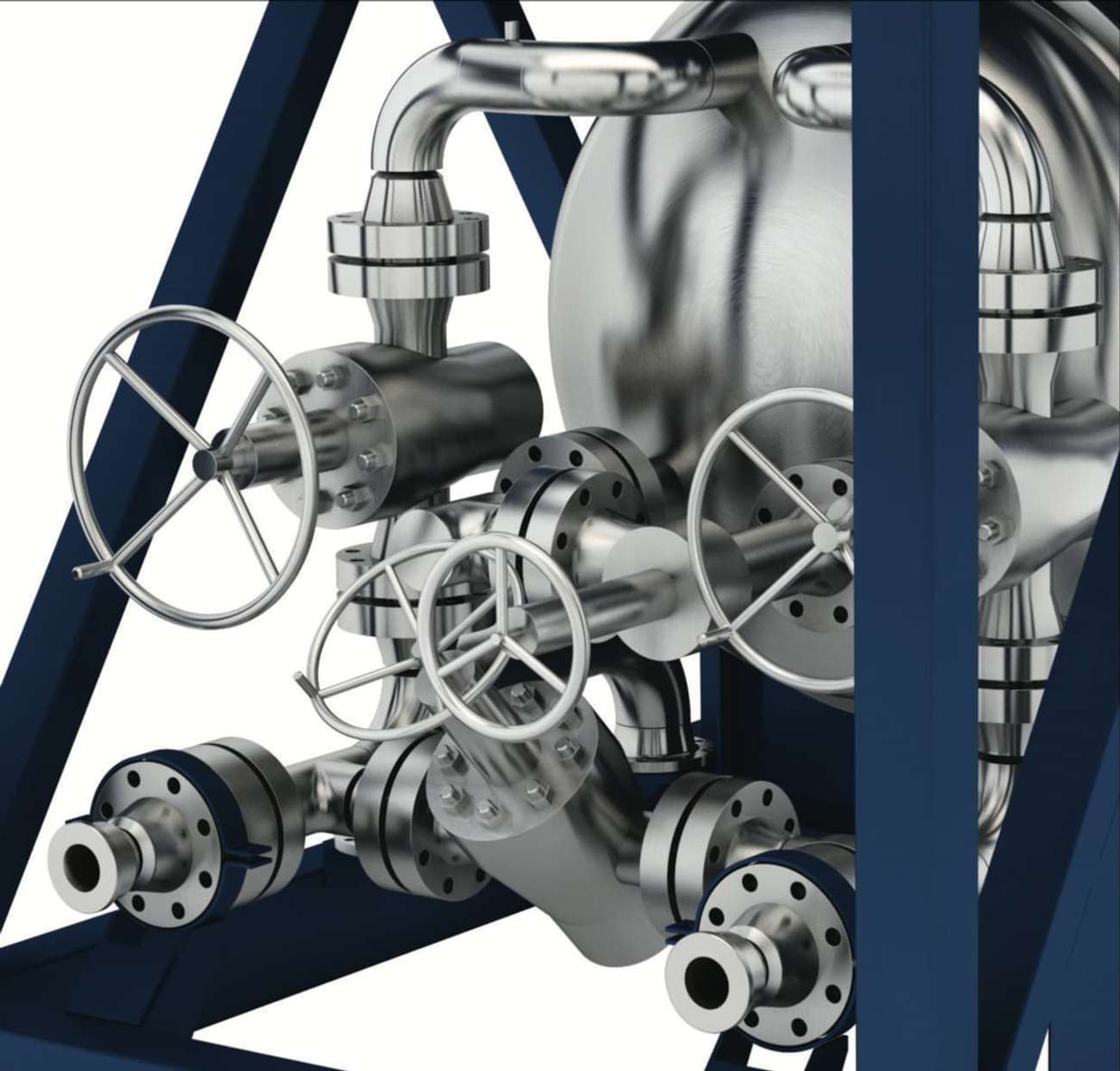

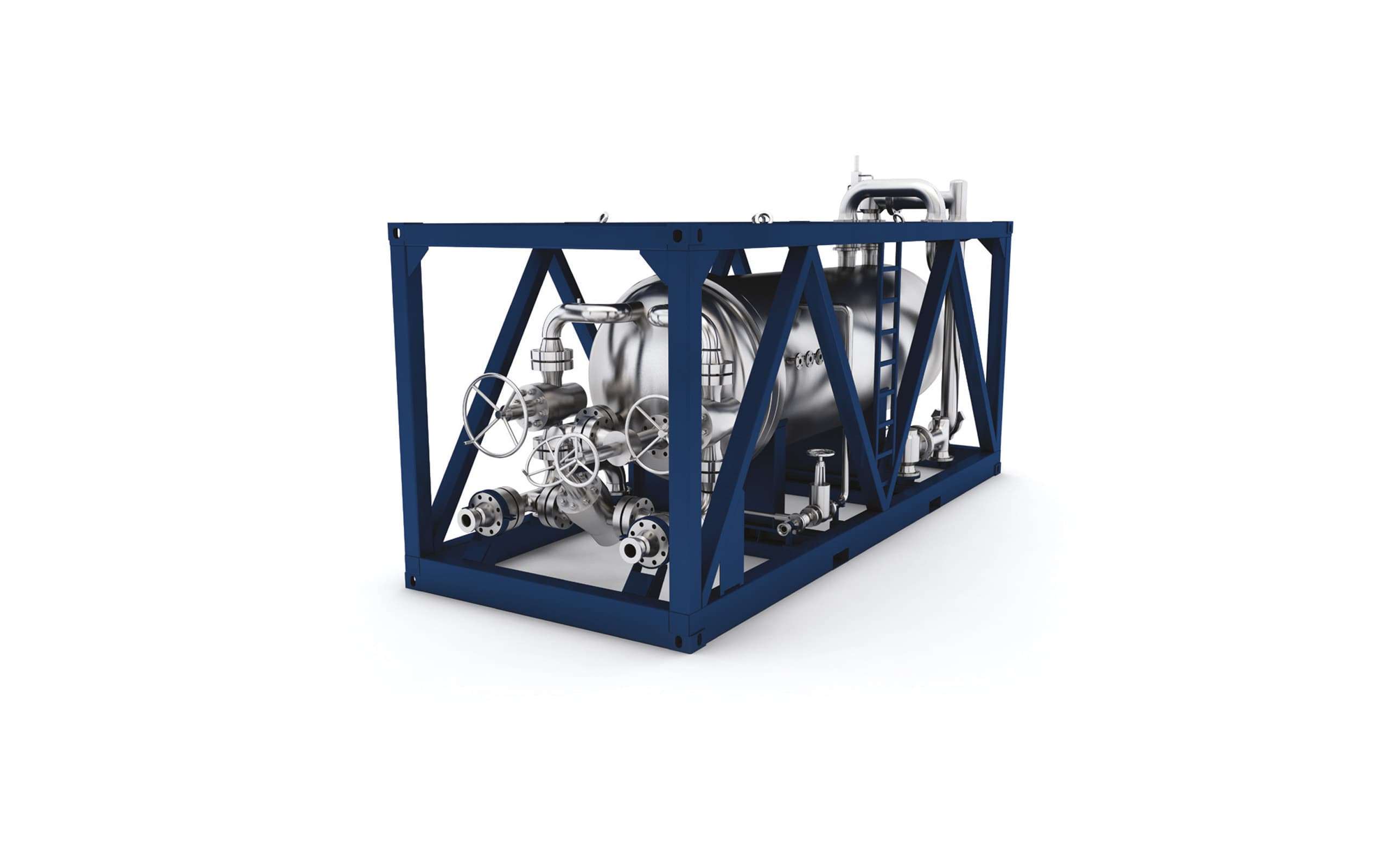

Multi Tube and Coiled Type Heat Exchangers

Used to raise the temperature of the well effluent to prevent hydrate formation

Product summary

The Heat Exchanger is positioned upstream of the separator and is used to raise the temperature of the well effluent to prevent hydrate formation from plugging of restricting the flow and to improve separation and burner efficiency by reducing fluid viscosity and breaking down emulsions.

Hunting provides a customised design, taking account of thermal design features, high / low pressure limits, temperature range, product mix and fluid flow capacity. Hunting’s manufacturing flexibility enables them to supply heat exchangers for a variety of volume requirements.