Titanium & Steel Tapered Stress Joints

Hunting Subsea Technologies' best in class Titanium & Steel Tapered Stress Joints (TSJs) offer unmatched reliability, performance and corrosion resistance - resulting in lower lifecycle costs and no downtime.

Product summary

Hunting Subsea Technologies' Titanium Stress Joints' (TSJs) field-proven operational history encompasses two decades of continuous subsea operation without a failure, allowing safe, efficient, and cost-effective pipeline connections to the offshore facility.

When you need durable, flexible, lightweight and long-lasting connections, TSJs are the superior solution for subsea operations.

Features

Highly durable & reliable

Resilient to high temperatures, high pressure and sour service conditions

Cost - effective across entire range of SCR

Outstanding fatigue life

Resistant to stiffness changes associated with temperature and load frequency

Immune to aging and gas absorption; no explosive decompression

Maintenance - free for long term, backend savings, including 20 years of continuous service without an operational failure ever

Readily available inhibitors for HF and other chemical exposure

Hunting Subsea Technologies' also manufactures Steel Stress Joints

Benefits

Adaptable and Flexible

Approved in major design codes for structures, equipment and other mission-critical applications requiring a strong, ductile metal

Easy installation with no depth limit to wet parking and no additional requirements or adapters

API-RP-2RD stress design rules apply directly, no rubber laminates

Uses common manufacturing and NDE methods (monolithic mental structure)

Lighter weight and safer to handle offshore improve CAPEX and OPEX

Multiple Mounting Options

Standard TSJ porches

Welded TSJ porch structure, our most commonly used mounting system

Adapters for FJ porches

Used for SCR tiebacks to existing facilities with spare FJ porches

Scope & Supply

TSJs have three primary interface points:

• Platform pipe above • Riser pipe below • Bushing for riser hang off

The upper platform interface is a weld allowing flanged or diverless connectors.

At the lower riser interface Hunting Subsea Technologies can supply fatigue-rated girth welds and a hang-off collar attached to customer supplied riser pipe.

Top Tensioned Riser (TTR) System

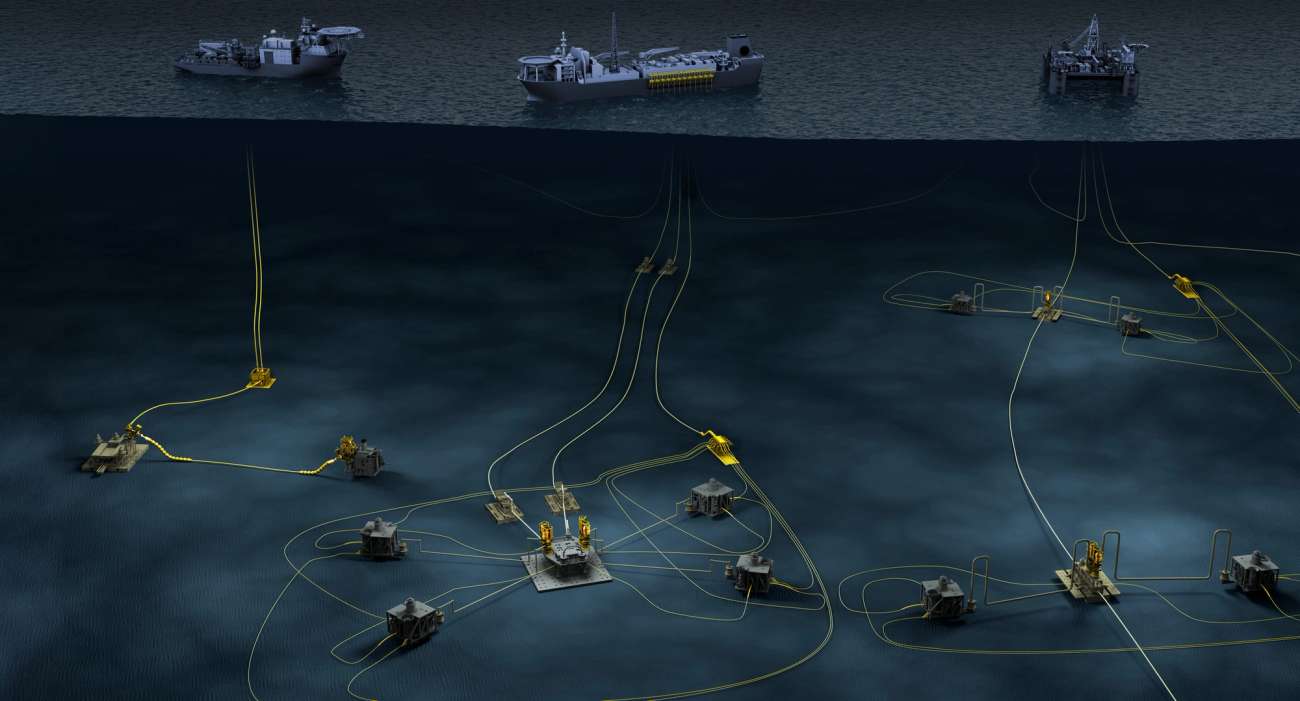

Hunting Subsea Technologies has provided over two hundred thousand feet of TTR riser systems to more than a dozen major deepwater projects, domestic and international.

These TTR joints are typically connected using Hunting’s Subsea Technologies proprietary RTI-SD riser connectors, which are weld-on pin by box style premium connections featuring dual metallic interference seals, proprietary high fatigue thread forms, compression load shoulder, and optional hang-off shoulders for easy riser handling and installation.

Hunting Subsea Technologies TTRs include both single (40ft) and dual pipe (60ft) standard joints along with a variety of specialty joints, including tensioner joints, length adjustment joints, keel joints, and tapered stress joints. Offered in either steel or Titanium. Hunting Subsea Technologies TTR keel joints include our patented shrink-fit centralizer for enhanced fatigue life. Hunting Subsea Technologies TTR tapered stress joints can be provided from either steel or titanium, dependent on loading and fatigue requirements.