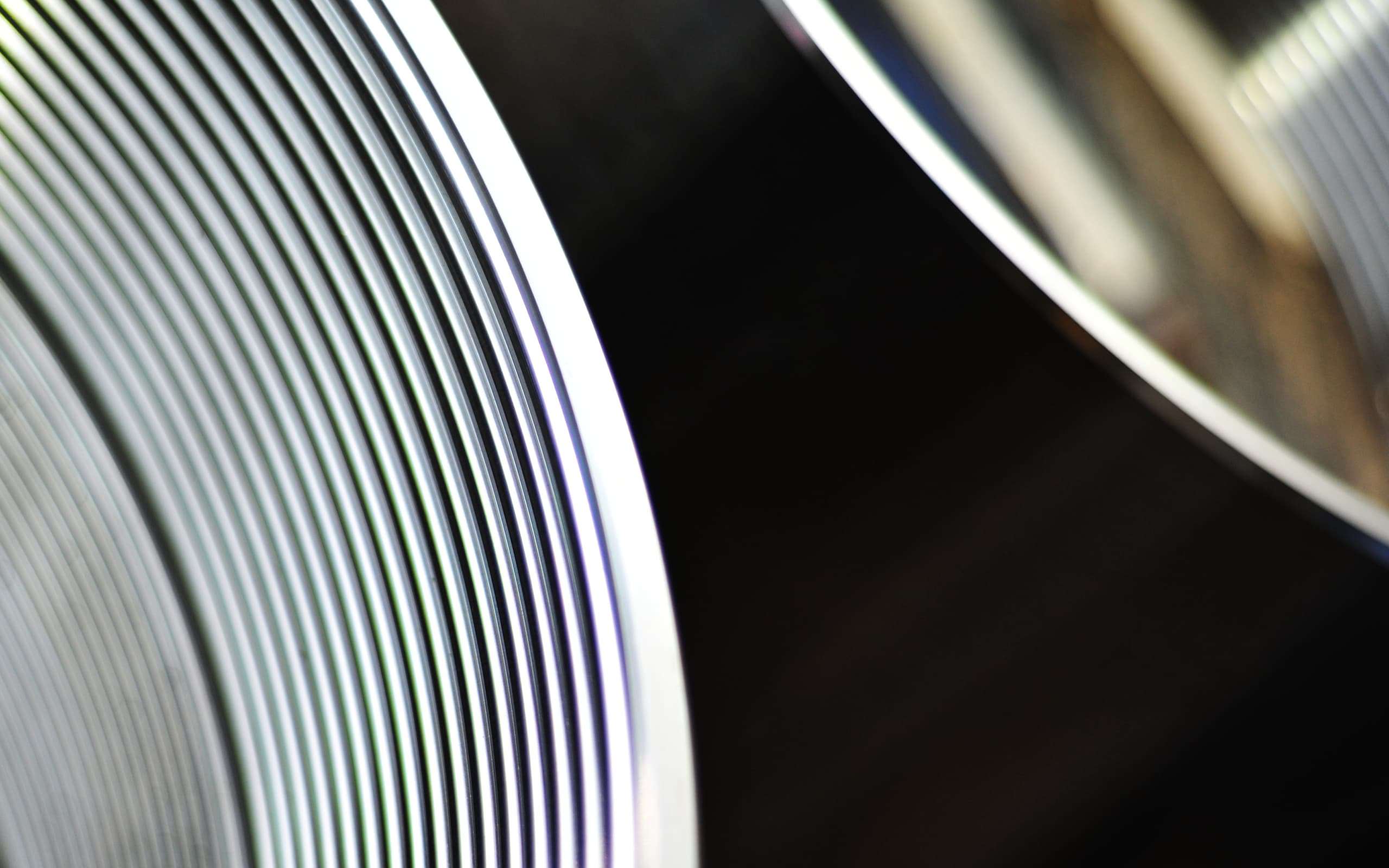

Premium Threading Services

Using its global network of threading facilities, Hunting can offer both premium and API connection threading machined onto manufactured and free-issue components.

Product summary

Hunting has established a global network of manufacturing facilities capable of machining Hunting Proprietary connections, API and licensed threadforms onto full length and accessory components from 1.9 inch to 20 inch OD.

Influenced by Lean Manufacturing and Six Sigma principles, Hunting’s facilities are organised in cellular processes, with separate threading lines for range 3 casing, tubing sizes, large diameter (up to 20”), dedicated pup joint and coupling manufacturing lines.

All are fully automated with separate handling systems, surface finishing and torque operations, ensuring quick deliveries and promoting safe operations. This allows high volume production of multiple orders simultaneously, for example threading both the tubing string and the associated accessories at the same time.

Features

API,Hunting Proprietary connections and licensed threadforms offered

Threading of full length and accessory components from 1.9 inch to 20 inch outside diameter

Torque make-up of couplings and ancillary components such as float equipment

Surface finishing processes such phosphating as and bead peening undertaken

Non-destructive test inspection

Swaging and stress-relieving for flush and semi-flush connections

Benefits

High volume simultaneous production of full length and accessory components

Experienced technical, sales and manufacturing personnel available 24/7, 365