Product summary

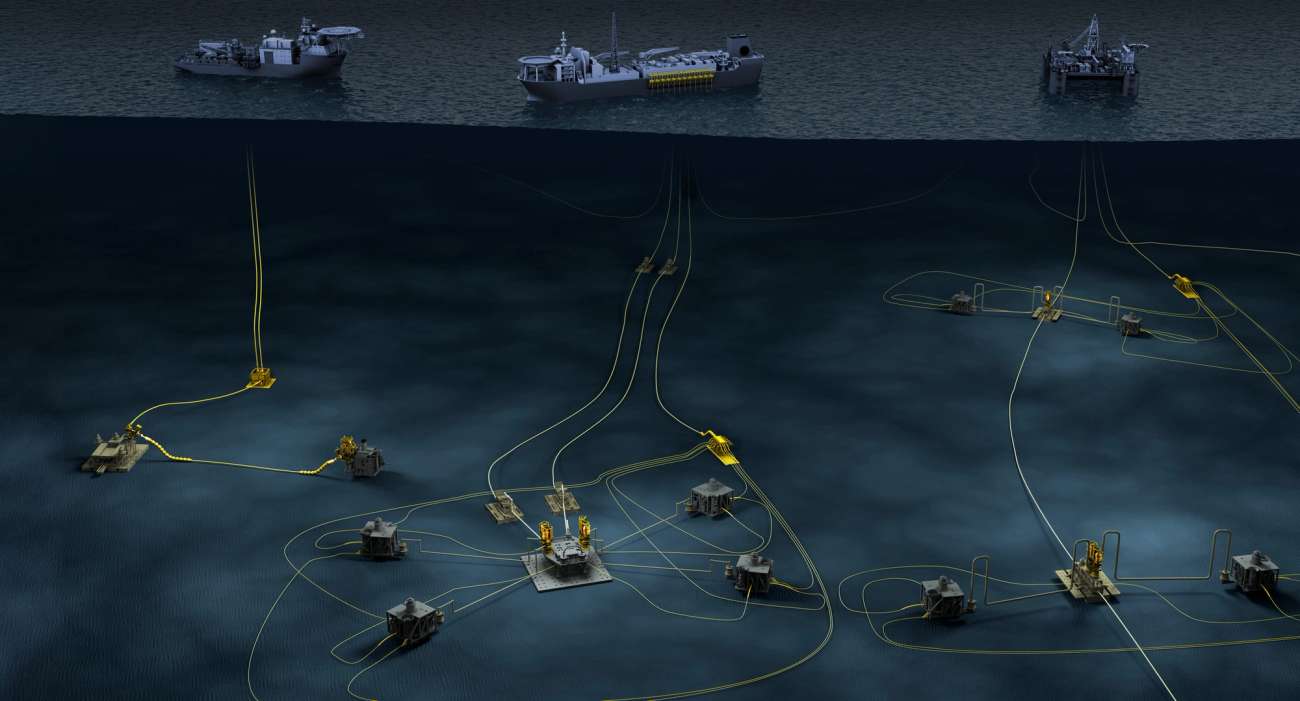

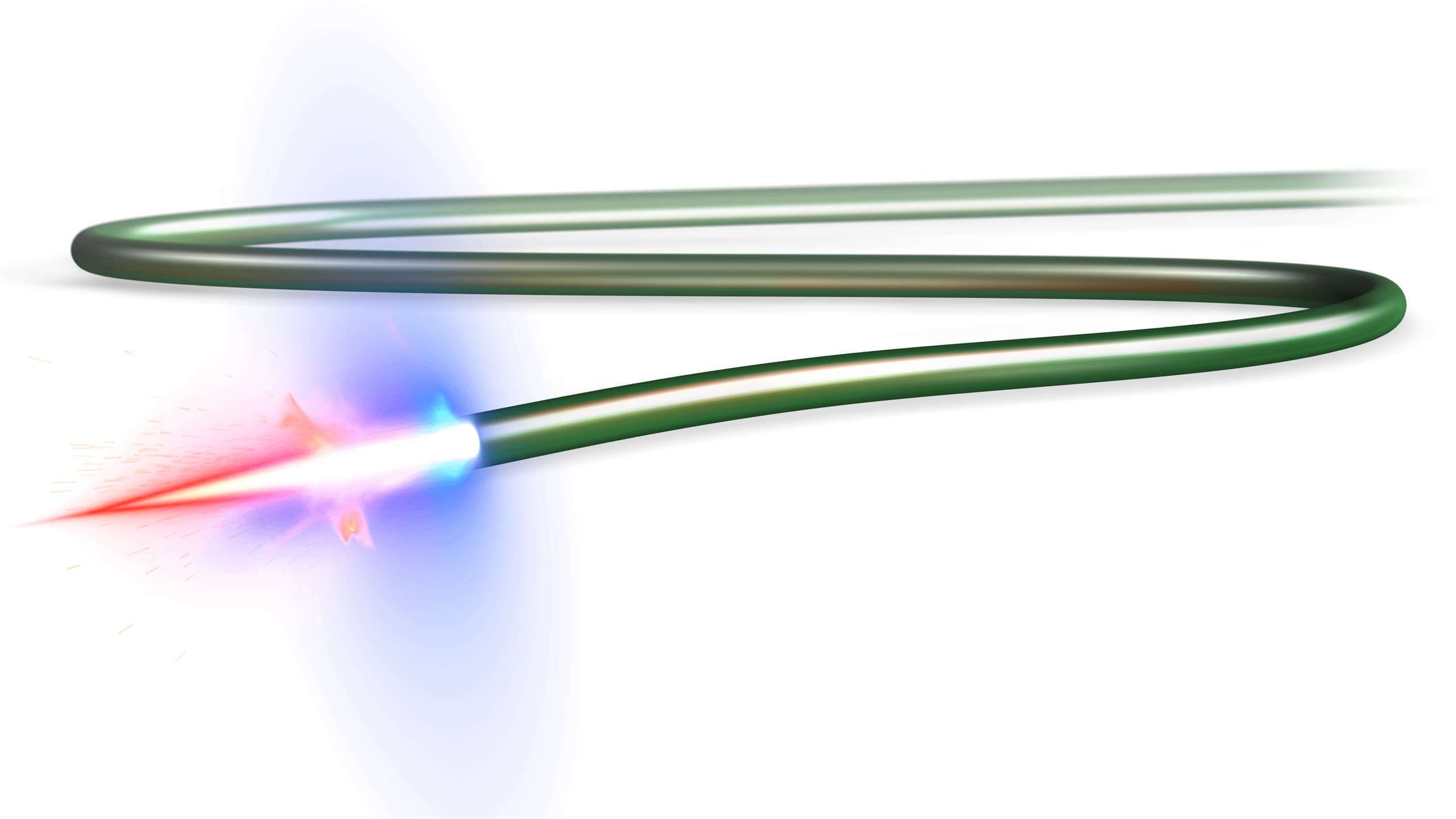

Hunting Detonating Cord is designed for use in perforating systems.

Both RDX and HMX products have been successfully deployed in downhole service applications within appropriate operating ranges (reference time and temperature chart).

Hunting’s detonating cord is manufactured at our API and ISO certified energetics facility which continues to be a world’s leader in shaped charge manufacturing. The RDX and HMX detonating cord undergoes extensive quality control and testing through Titan division’s dedicated research and development group.

Application Recommendations

Select detonating cord that has physical and performance characteristics consistent with correct blasting methods and the type of explosive materials being used.

Never use detonating cord in exposed well bore conditions.

Avoid damaging, crimping, or severing detonating cord prior to firing.

Always cut detonating cord with sharp, single blade cord cutters to avoid pinching.

Avoid loops, sharp kinks, or angles that direct the detonating cord back toward the oncoming line of detonation.

Never attempt to cut detonating cord with a blow from a sharp or blunt object.

Do not cut detonating cord with devices that produce metal-to-metal contact, such as scissors, wire cutters, crimpers, or similar instruments

Never saw detonating cord; it may explode and kill or injure.

Transportation Storage and Handling

For maximum shelf-life, detonating cord must be stored in cool, dry, well-ventilated place Recommended shelf life, under proper storage conditions, is 10 years from date of manufacture.

Detonating cords must be transported, stored, handled and used in conformity with all federal, state, provincial and local laws and regulations.